Filtration technology plays a vital role in many fields, especially in air purification, drinking water treatment, industrial waste gas emissions, and other areas. With the intensification of environmental pollution, people's demand for efficient and sustainable filtration solutions is also increasing.

As a new type of filtration technology, aluminum-based activated carbon filter screens have gradually been applied in various industries due to their unique materials and efficient filtration performance.According to a study by the Environmental Protection Agency (EPA), the combination of aluminum and activated carbon in filtration systems can significantly enhance the removal of particulate matter and volatile organic compounds (VOCs) from air and water. This is due to the synergistic effect of aluminum’s structural strength and the high adsorption capacity of activated carbon. The EPA further supports this technology's efficiency by stating that it "offers a high level of filtration at reduced operational costs, making it ideal for large-scale environmental applications."

What is Aluminum Based Activated Carbon Filter?

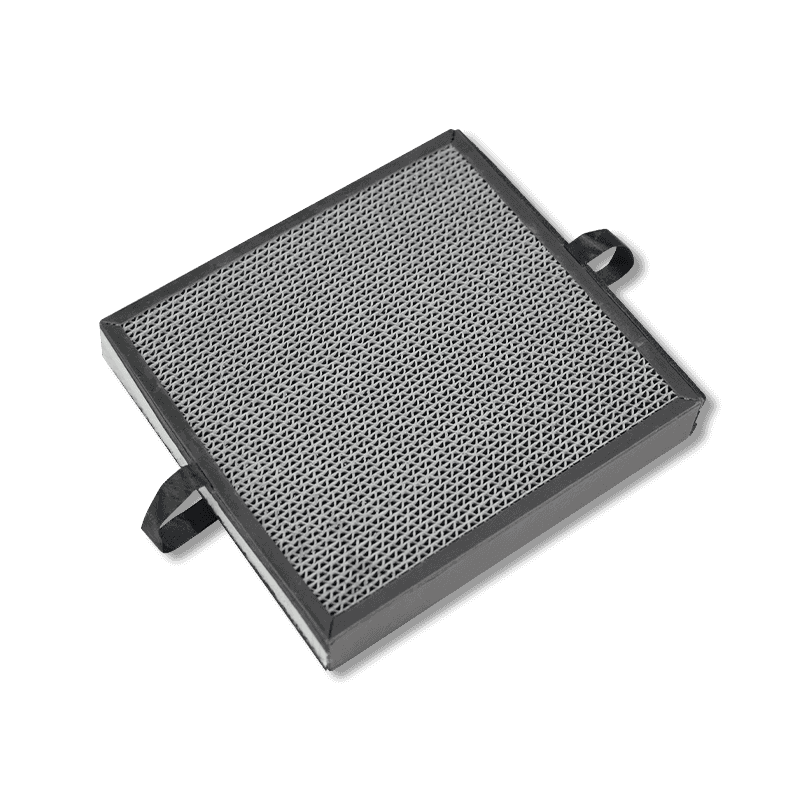

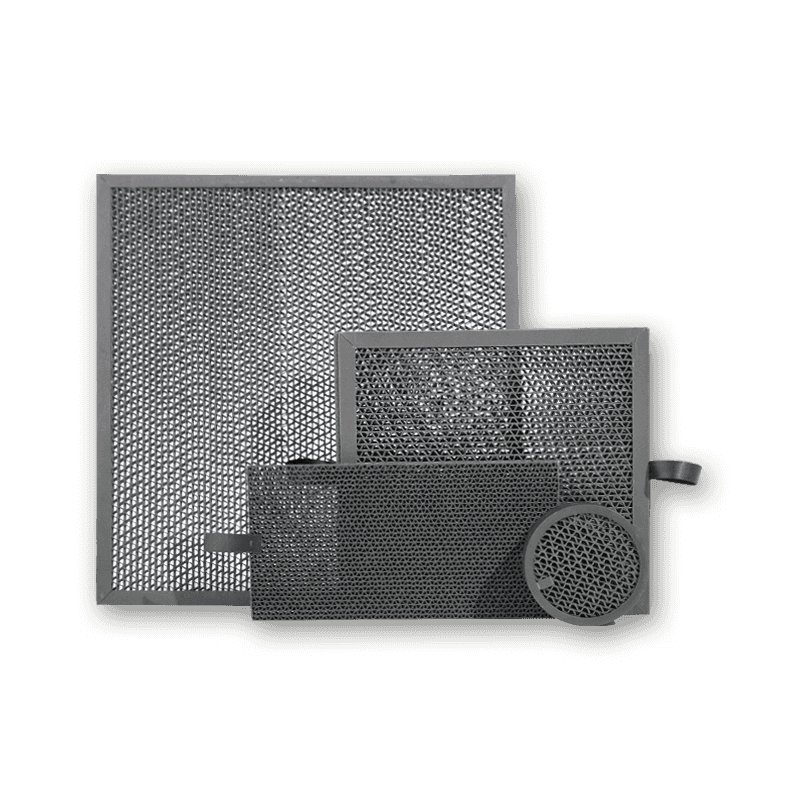

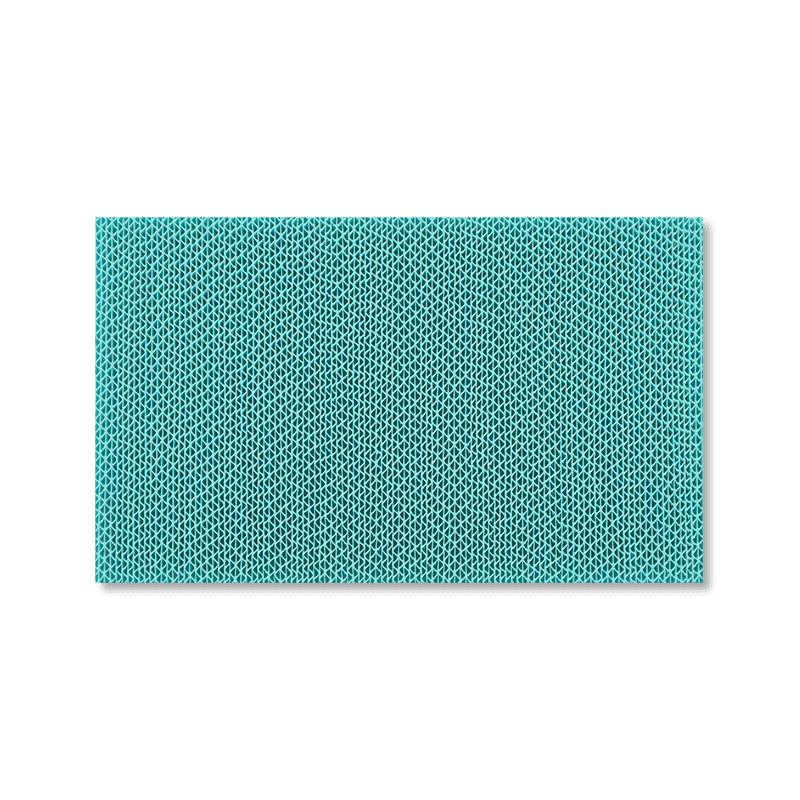

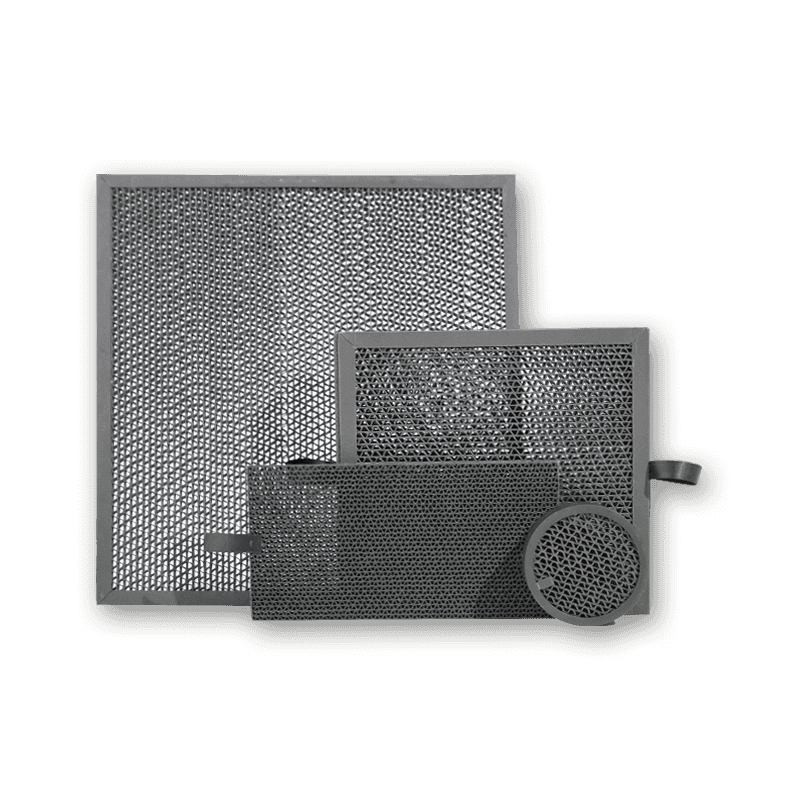

Aluminum-based activated carbon filter is a filtration technology that combines aluminum substrate and activated carbon. It uses the adsorption properties of activated carbon to remove harmful substances from the air, while using the stability and durability of aluminum-based materials to enhance its overall performance.

Aluminum-based material: Aluminum is a lightweight, corrosion-resistant metal that acts as a support to enhance the durability and stability of the entire filtration system.

Activated carbon: Activated carbon has a large surface area and many tiny pores on the surface, which can effectively capture pollutants such as harmful gases, bacteria, chemicals, etc.

Key advantages of aluminum-based activated carbon filters

Compared with traditional filtration technologies, aluminum-based activated carbon filters can provide stronger adsorption effects. Aluminum-based materials have excellent corrosion resistance and can remain stable in various harsh environments, and activated carbon itself has a long service life. This filter is durable and reduces the frequency of replacement. The material of aluminum-based activated carbon filters is recyclable and meets the requirements of modern environmental protection. Aluminum-based materials are sustainable resources, and activated carbon can also be reused through regeneration and treatment to reduce resource waste.

Compared with other traditional filtration technologies, aluminum-based activated carbon filters are lighter and easier to install and use. This makes it more convenient in some application scenarios that require frequent movement or limited space. Although aluminum-based activated carbon filters may have a slightly higher initial cost than traditional filtration technologies, their long service life and low maintenance costs make them more cost-effective in long-term use.

Traditional activated carbon filters usually use plastic, metal mesh, etc. as carriers, while aluminum-based activated carbon filters use aluminum as support to provide higher strength and stability. Aluminum-based materials themselves have higher resistance to high temperatures and corrosion, and have a longer service life. For example,Honeycomb Pore Granular Activated Carbon Filter usually rely on granular activated carbon to adsorb pollutants, while aluminum-based activated carbon filters are attached to aluminum-based supports through activated carbon coatings. This structure helps to improve filtration efficiency and reduce wind resistance.

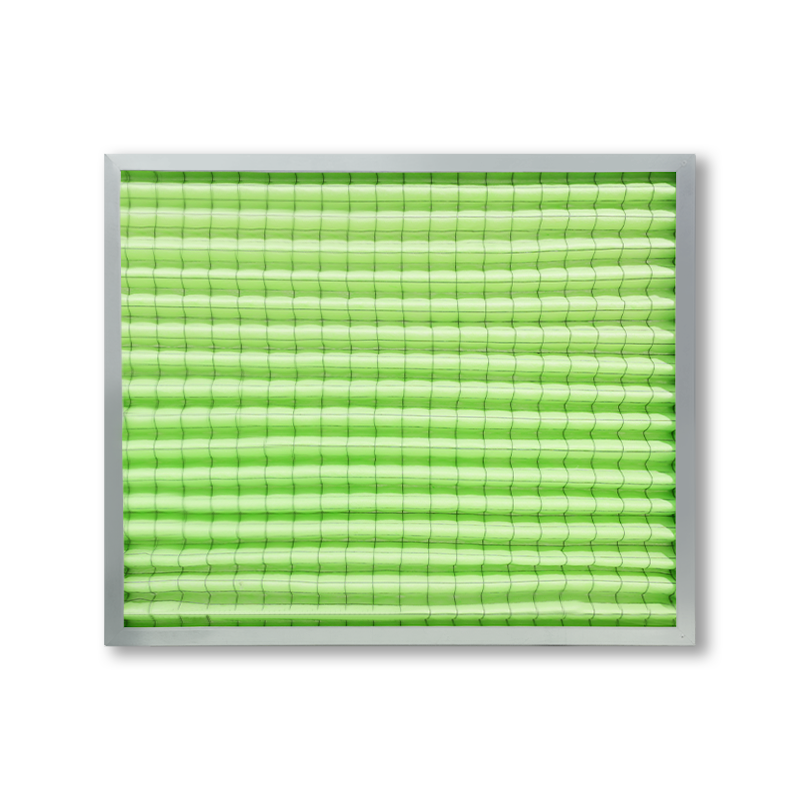

Corrugated paper-based activated carbon filter screen adsorb pollutants through a porous structure, but aluminum-based materials have advantages in high temperature resistance and durability. The aluminum support of aluminum-based activated carbon filters makes them perform better in high temperature environments and have a longer service life.

Application of aluminum-based activated carbon filter

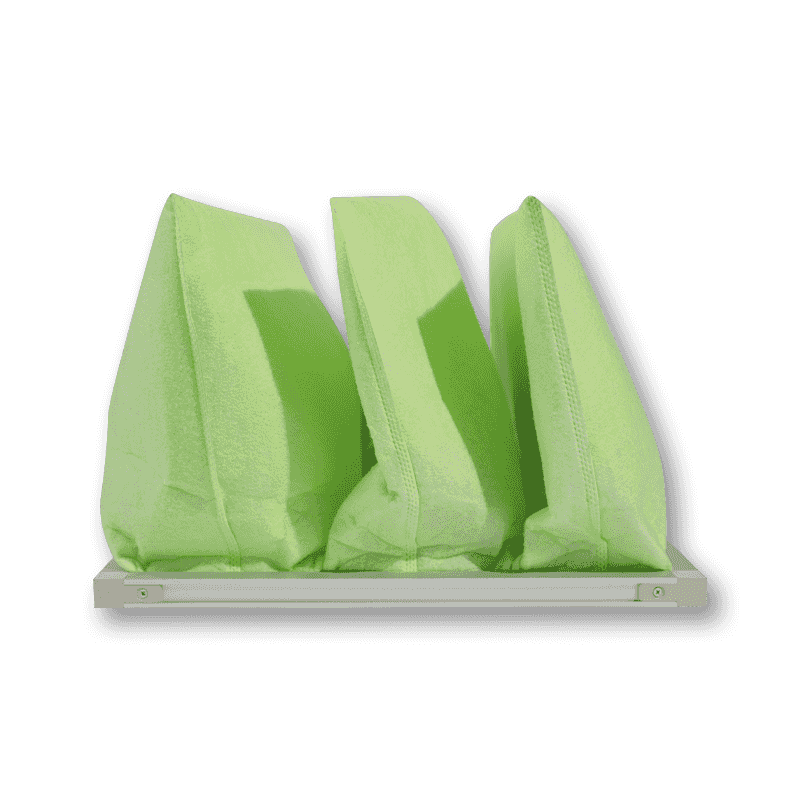

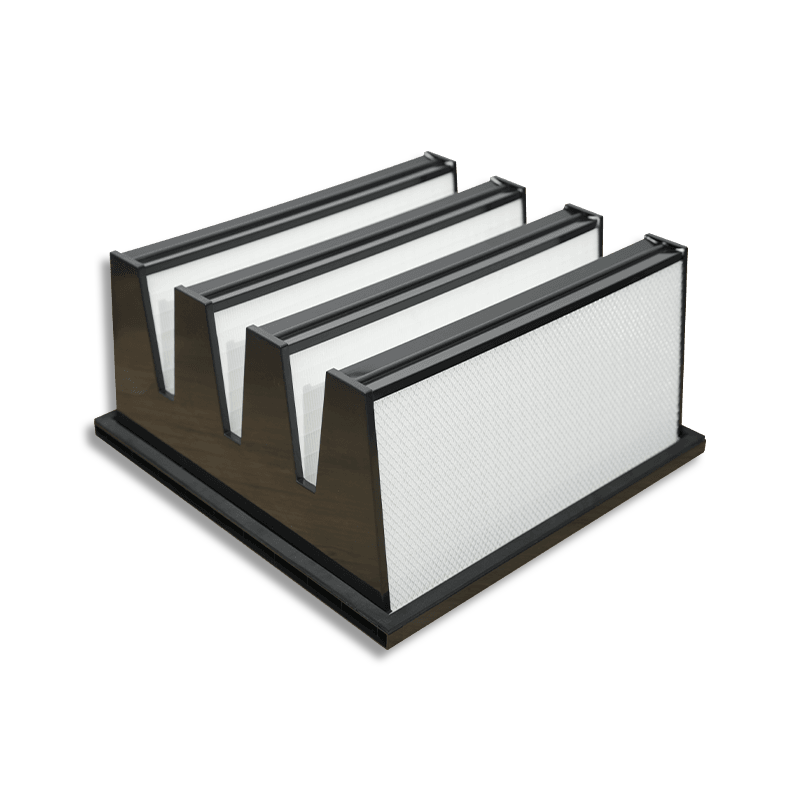

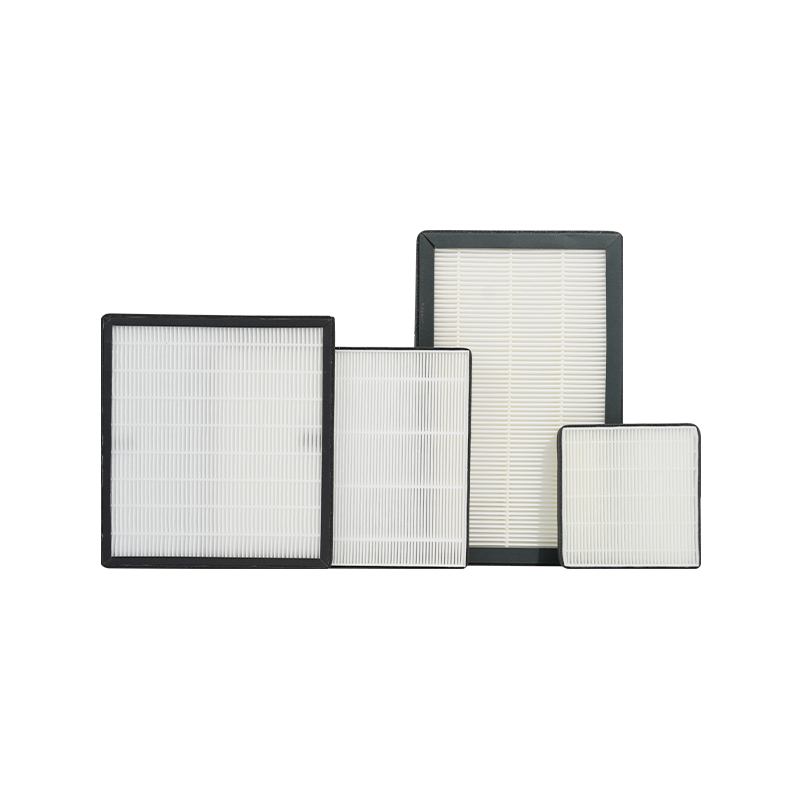

Aluminum-based activated carbon filters can also be combined with HEPA to meet more diversified air purification needs.

Aluminum-based activated carbon filters are widely used in household and industrial air purification systems, such as air purifiers, household air conditioners, commercial air conditioners and other equipment. They can effectively remove harmful substances in the air, such as formaldehyde, smoke, odor, etc., and provide a fresh air environment. In the automotive industry, aluminum-based activated carbon filters are used in car air purification systems to help remove odors, PM2.5 and other harmful substances in the car, and improve the driving experience of car owners. In some industrial applications, aluminum-based activated carbon filters are used for exhaust emission control. It can effectively adsorb and remove harmful gases, help companies comply with environmental regulations, and reduce pollution to the environment.

Prospects of aluminum-based activated carbon filters

In the future, the research and development of aluminum-based activated carbon filters will focus on improving their adsorption capacity and service life, exploring more efficient activated carbon treatment methods, and optimizing the performance of aluminum-based materials. With the development of smart home and Internet of Things technologies, aluminum-based activated carbon filters are expected to be combined with smart air purification systems to achieve automatic monitoring and adjustment to better meet user needs. Environmental protection requirements have promoted the innovation of aluminum-based activated carbon filter materials. Future research and development directions will focus on the sustainability and recyclability of materials to better adapt to the trend of green environmental protection.

English

English Español

Español 日本語

日本語